- Raft hard to remove simplify 3d install#

- Raft hard to remove simplify 3d plus#

- Raft hard to remove simplify 3d free#

So it's unlikely unless the user goes out of their way making adjustments for this to be incorrect. #5 first layer speed definitely can affect it, but most slicers including Ideamaker and Simplify 3D do have correct first layer speed as defaults settings. By preheating, now you know first layer is at the right temp. The wait time for the bed sensor to reach temp at the start of a print does not mean the surface is that temp by the time you start printing. The other factor is that in a situation where you are worried about warp ALWAYS preheat the bed long before you print. Again, here is a user setting that should be addressed. I MUCH prefer 50-60C bed for PLA adhesion. Again, as I pointed out, I feel that the defaults are actually incorrect in Ideamaker and too cold. Again, this is a matched set and so the details might be specific to certain combos, but using the wrong heat for the wrong material or bed surface- even if everything else was right can contribute to an adhesion failure. #4 Bed temperature specific to the material and bed surface combination.

Raft hard to remove simplify 3d free#

#3 Surface prep- clean oil free, fingerprint free correct chemical surface for the material being printed.

You should be getting a go/no-go feel just from the first outline. This is a skill the user must master and be able to diagnose while watching the skirt or brim go down on the start of a print. Again, if there was any one thing that the user is responsible for setting up- this is it at the physical level. If that squish is not even or uniform (bed leveling is what causes it to be uneven) or overall global Z gap (the mechanical screw hitting the Z axis homing switch) ultimately makes or breaks this rule.

#2 First layer gap and leveling- The only way first layer sticks is the bead of hot plastic must be squished oval to increase surface contact into the bed. One color or one brand may react and be more likely to warp than another. Different material has different rates of shrinkage and is the primary force behind warping. The material details is the entire reason why it warps. The top things that affect bed adhesion/warping: It prints faster since it's only a single layer.Īgain, if you read the the guide, they nearly verbatim say what I have been saying for years. It's more surface area to stick to the bed. Brim gives the same effect of surface adhesion. If you need surface adhesion, ALWAYS choose brim before raft. It adds more time to the print and again even when it does work impacts the surface finish of the final part. Raft simply is laying a big flat plastic layer and then you have to go back and try to peal off your print without causing surface damage.

It's the training wheels of 3D printing when you cannot get a user to properly level and set first layer gap or for that just absolutely impossible project that has such limited surface contact- then raft makes some sense. Raft is a total waste of time and material and causes more issues than it solves. This is my opinion, but it's based on years of experience. You should also preheat the bed 10-15 minutes BEFORE you start the print as it takes time for the surface to reach the actual temp before you go printing a layer on it.

Raft hard to remove simplify 3d install#

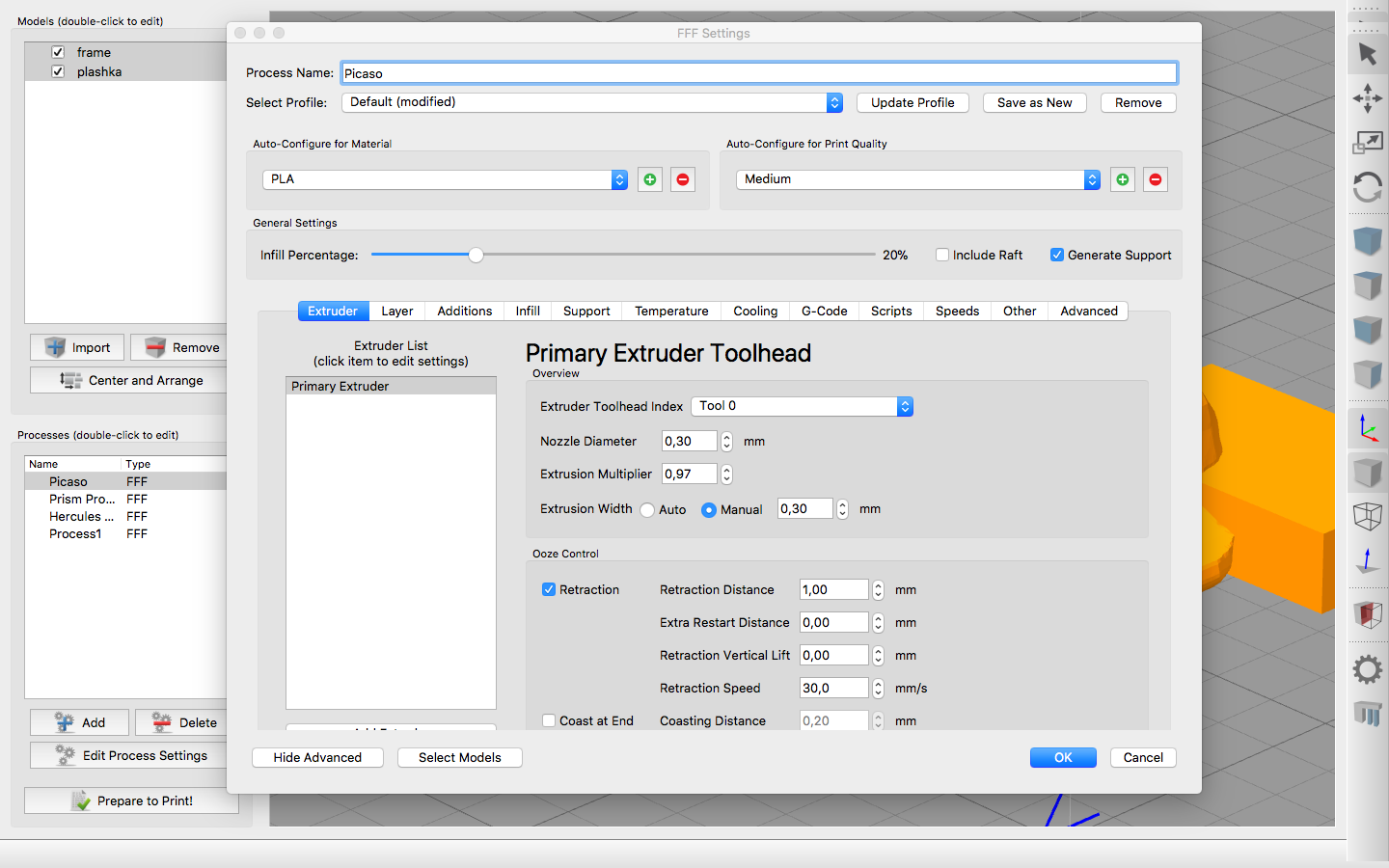

I had to edit the default profiles every time I fire up a new install of Ideamaker because that that one right there.

Raft hard to remove simplify 3d plus#

I have long been upset with the defaults in both ideamaker and copied over to other slicers like S3D.Ĥ0C is simply not enough for good bed adhesion and I use 50C with glass + aquanet hairspray or 60C when using my N2 Plus with it's factory Buildtack surface. I assume you are using PLA based on your temps and other settings so no, do not block the fan ducts.

0 kommentar(er)

0 kommentar(er)